After five years of anemic economic recovery, manufacturers continue to add inventory to their books much faster than GDP growth. In order to better manage inventory levels while still ensuring the right part is in the right place at the right time, manufacturers are increasingly relying on advanced information management solutions, according to a survey released by PwC US in collaboration with Manufacturers Alliance for Productivity and Innovation (MAPI).

Further, inventory turns – which indicate whether the supply chain is getting more efficient at moving goods from suppliers to customers – have declined steadily since 2011. PwC and MAPI surveyed senior executives from 75 global manufacturers (with U.S. headquarters) to better understand this decline in inventory performance and polled respondents on the effectiveness and benefits of using advanced inventory data management strategies to reduce inventory.

“Inventory is often considered by manufacturers to be the most valuable category of assets on their books; however, it can tie up large amounts of cash and diminish in value for a host of reasons,” said Stephen Pillsbury, principal in PwC’s U.S. industrial products practice. “As a result, it has become common practice for manufacturers to minimize inventory as much as possible without hurting customer service levels. While they continue to focus on managing inventory, they seem to have reached a point of diminishing returns and are now turning to advanced information management solutions to further reduce their inventory.”

Nandu Gopalun with Ultriva by Upland recently shared some of the benefits of effective real-time information management solutions. He noted, “Real-time information helps to ensure correct scheduling, planners and buyers to plan components accurately, and suppliers to react quickly to the changes”.

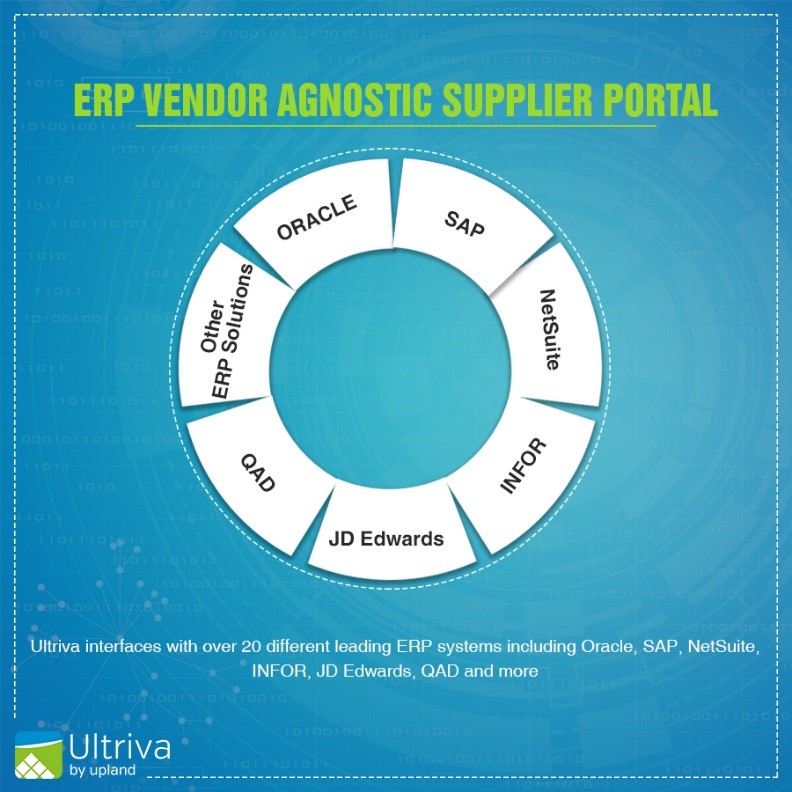

When it comes to enabling agility, responsiveness and operating flexibility, 37 percent of respondents reported that their core ERP system was either not very effective or ineffective. Conversely, the other respondents with effective ERP systems were quite bullish on the usefulness of their supply chain visibility (SCV) systems when it comes to replacing inventory and costs with actionable and timely data.

Interestingly, companies with ineffective ERP systems experienced an average annual margin erosion of 3.5 percent while those with effective systems in place experienced an average growth of 2 percent. Companies with both effective ERP and SCV systems had even higher margins at 2.4 percent. Put another way, we found a clear connection between strong margin performance and effective ERP implementations.

Gopalun noted that solutions like Ultriva by Upland are not in conflict with ERP solutions and in fact complements ERP.

In regards to inventory turns, almost half of those surveyed said their supply chain system was effective or very effective while one third said their system was not very effective or ineffective at replacing inventory and costs with actionable and timely data. When comparing the two groups, the companies with effective SVC systems outperformed the ineffective ones by 30 percent.

“Information management systems matter because they get the right information to the right place at the right time in order to improve effectiveness,” said Cam Mackey, SVP, Operations and Partnerships, MAPI. “To that end, many companies have invested a great deal of time and money implementing ERP and SVC systems. Together, these platforms can provide manufacturers with detailed information including orders, lead times, stock quantities and locations. Effectively integrating these information systems enables manufacturers to do a better job of synchronizing supplier deliveries with production schedules and customer orders, resulting in improved customer service and less overall inventory.”

Gopalun said, “In an effort to improve supply chain management, many companies are embracing SCV systems – enabling companies to track and manage raw materials, work-in-process, and finished goods across the extended supply chain. It reduces inventory across the supply chain, not only with in four walls of the plant but also with their suppliers and with their customers.

Of those surveyed, 70 percent reported having a SCV system in place.

As effective systems drive better margin growth and higher turns, companies are still experiencing inventory growth and supply chain issues. When asked about the factors having the biggest impact on supply chain visibility, uncertainty of supplier deliveries and unpredictable customer demand were among the responses most cited. While SCV systems are intended to link customer demand to production schedules and supplier orders/deliveries, respondents continue to cite problems with forecast accuracy.

Read More