The First Requirement for E2E

Last week, I wrote a blog highlighting the clear need for a cloud-based SaaS solution to establish the “End to End Pull” process across manufacturing companies (or E2E pull process or just E2E). In that blog, eight basic requirements for developing an E2E pull model were listed.

Over the course of the next several weeks this blog will address one requirement at a time. Today’s blog will address the first requirement – the need for a collaborative transactional portal. End to End, as the name signifies, allows manufacturers to actively collaborate with customers for actual demand and synchronize with suppliers for replenishment. E2E offers a better solution to balancing supply with customer demand through procurement strategies, materials and inventory policies tied to actual demand signals. Many suppliers want to provide sufficient service levels to customers and turn supply replenishment and synchronization into a competitive advantage.

Managing the Disconnection

In today’s world manufacturers, suppliers, and customers are disconnected. Customers communicate via Sales Orders (EDI, email, fax etc.) while suppliers get forecasts, Purchase Orders and MRP exceptions. A change in demand is not easily communicated to the upstream supply chain. The data is resident in ERP/MRP systems, planning tools, S&OP spreadsheets and email templates. It is not uncommon to see a big team of demand and supply planners who are constantly gathering and accumulating data and generating more consolidated, cross-functional and cross-tabulated spreadsheets for companywide distribution via emails.

Seeing the Data from a Single Source

Like the evolution of social media, it is important that manufacturers, customers, and suppliers view the data from a single source when they need it. Transactions are done in the respective time zone, by users who own a small piece. The data flows in real-time and is readily available for the next person to view, update, transact, or analyze. The data is no longer “living in isolation”, but it is available with clear context. That means changes in customers’ demand can lead to a rescheduling of production...which in turn impacts raw material replenishment. We all know this single vantage may be difficult to achieve, but the first criteria is the availability and access to the data.

The collaborative, real-time portals form the foundation for the E2E Pull design. The stronger and more comprehensive the foundation, the more flexibility can be built into the process. An application that is in the cloud, with the ability for users around the world to access using a simple browser, seamlessly interfaces to existing business systems, with transactions happening over secure network, interconnecting scanners, RFID, mobile devices, driven by actionable information, and exception based management, allows you to jump start the implementation of E2E pull replenishment.

The collaborative, real-time portals form the foundation for the E2E Pull design. The stronger and more comprehensive the foundation, the more flexibility can be built into the process. An application that is in the cloud, gives users world-wide access via a simple browser, seamlessly interfaces with existing business systems, allows transactions to happen over a secure network, is driven by actionable information and exception based management, and interconnects scanners, RFID, and mobile devices, allows you to jump-start the implementation of E2E pull replenishment.

It is Happening Now

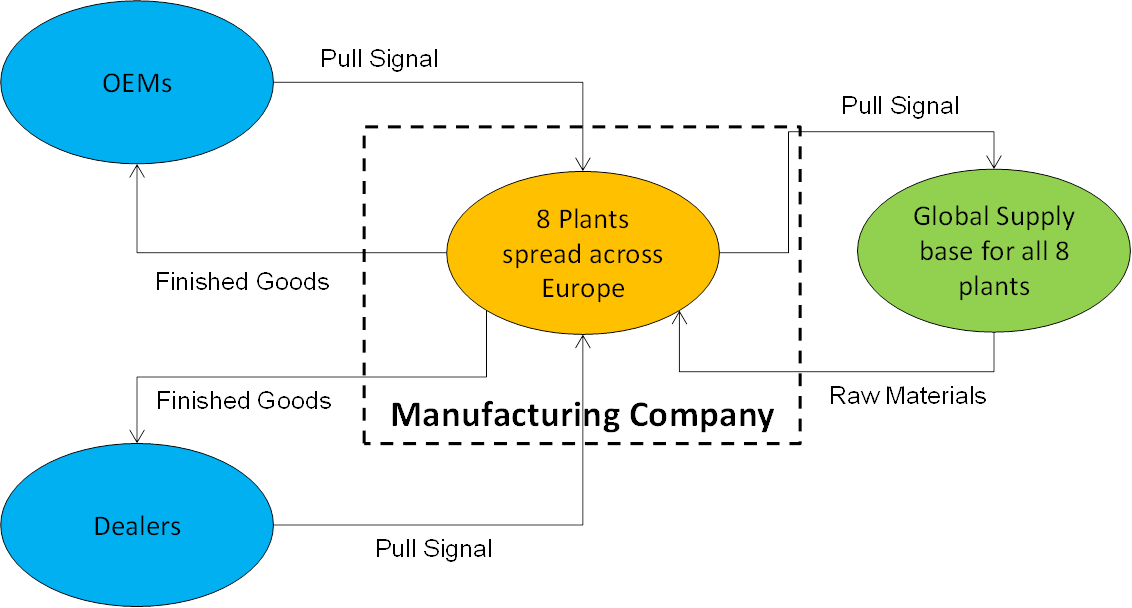

One of our customers, a large diversified manufacturing company, has been using this model for the last seven years. Their division in Europe, which manufactures a range of compressors, is collaborating with their OEMs for large capacity compressors while integrating with their Middle Eastern dealers for small and medium capacity compressors. The pull process allows them to sense demand changes while synchronizing the same with their global supply base.

The Bottom Line

This company gained visibility in to the demand and supply side of their business. By right-sizing the inventory mix, they improved their inventory turns. However the most important benefit came from an unexpected area. The company was able to guarantee service levels (parts always available for their customers) and thereby charge a higher price. So this E2E process was a true win for them.

I want to personally encourage you to see what these collaborative portals look like; please contact Ultriva to learn more about E2E Pull.